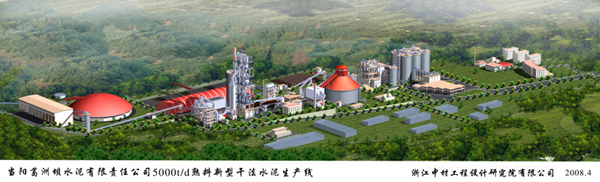

3000 Tons/Day New Type Dry Process Cement Production Line

In the original engineering design process, Pengfei Group tries to perfect the cement process flow and reduce material transportation to save energy. It also tries to strengthen measurement work to reduce raw fuel loss and production loss.

Description

In the original engineering design process, Pengfei Group tries to perfect the cement process flow and reduce material transportation to save energy. It also tries to strengthen measurement work to reduce raw fuel loss and production loss. High-accuracy measuring devices are adopted in every link of this dry process cement production line. It is eco-friendly. High efficient dust collectors are installed to control dust emission and protect the environment. Waste gas from this cement making machinery is purified before exhausted into the air. The central lab of the factory tests all raw fuel, semis and finished products. The air compressor station provides compressed air for cement production.

Features of Energy-Saving Techniques

A set of self-developed energy-saving technologies are employed in this dry process cement production line. The unique features are listed below:

1. We introduce advanced technology to manufacture single stage hammer crushers. It makes the limestone crushing process simple. This cement making machinery is of low power consumption.

2. We adopt a closed circuit grinding system in this 3000 tons/day new type dry process cement production line. Roller press and Ф4.6 m× (10+3.5) m middle-discharge mill are used to grind raw materials. It saves about 5 kWh/t electricity per unit compared with traditional middle- discharge mills and air swept mills.

3. This cement making machinery is equipped with high efficient vertical roller mill grinding system. This system is used to prepare coal powder. It saves electricity by about 11.0 kWh/t per unit compared with the traditional cement process flow which is composed of air swept ball mill, dynamic coarse powder separator and high concentration air box pulse bag type dust collector.

4. In the whole dry process cement production line, we use energy efficient equipment to transport materials to save power consumption. For example, we save about 2.5 to 3 kWh/t electricity per unit by using the bucket elevator to transport raw materials.

5. DCS computer control system is used to monitor and control the whole cement making machinery. It realizes stable control, optimizing operations and saving energy. We have successfully raised labor productivity.

6. In the 3000 tons/day new type dry process cement production line, we adopt high-performance cement equipment such as NC type double series low pressure drop five-stage cyclone pre-heater and calciner, NC type high efficient rotary kiln, NC type high efficient coal powder burner, and flow-control type cooler to calcine clinker. The thermal loss in clinker calcining is less than 750×4.182 kJ/kg.Cl. Overall power consumption is less than 58kWh/t.Cl.

7. Waste gas discharged from the preheater of this cement making machinery is used as heat source for drying raw material and coal powder. We adopt new technology cooler with a heat recovery efficiency of over 75%. It efficiently recycles heat from clinkers and raises the temperature of secondary air and tertiary air. Thermal loss in clinker burning is cut down.

8. Multi-channel coal injection pipe of this dry process cement production line is used in kilns. It reduces the rate of primary air entering kiln to about 10% and raises the volume of the high-temperature secondary air. It improves the burning condition inside kiln and raises burning efficiency.

Main Process Flow of This Dry Process Cement Production Line

1. Limestone Crushing

Limestone is delivered to hopper by auto-dumper and crushed by hammer crusher. A belt conveyer of this cement making machinery then transports the limestone to pre-homogenization yard. The limestone is then stacked in layers and reclaimed by cantilever stacker. It is finally transported to raw material batching station by belt conveyer. We install electromagnetic iron collector on belt conveyer to remove iron parts from limestone. A metal detector is added on the belt conveyer’s head to find remaining iron and to avoid damaging the roller press.

2. Raw Material Preparing

The raw material batching station of this new type dry process cement production line is composed of limestone bin, silica bin, iron ore tailing bin and wet fly ash bin. We install a plate feeder and a weighing feeder at the bottom of each batching bin. Raw materials are discharged respectively form weighing feeders in proportion. The mixture of materials is then fed into the small bin of the raw material roller press by belt conveyer.

3. Raw Material Grinding

After being extruded by the roller press, the mixture of materials is dried and classified by V type separator of this cement making machinery. Fine powder is then sent into raw material homogenization silo via air slide conveyer and bucket elevator. Coarse powder and wet fly ash are sent to raw material mill to grind and dry. It is sent back to the powder separator to classify. Waste gas is purified by electrical dust collector and exhausted into the air.

4. Raw Material Homogenizing

In the new type dry process cement production line, we build aФ18m raw material homogenization silo. Raw materials are inflated in the silo and then discharged into the mixing room. Materials are inflated and blended evenly. (ROOT blower is installed at the silo bottom to provide air flow). The homogenized raw material is then measured. It enters into the bucket elevator of this cement making machinery through air slide. The raw material is then sent into the two inlets of the pre-heater via distributing valve and air-lock valve.

5. Calcining

Raw material is preheated in the preheater and decomposed in the calcinator. It is then sent into kiln to calcine.The clinker is then cooled by grate cooler. Big block clinker is smashed by crusher. Together with small clinkers leaked into air chamber, smashed clinker is transported to clinker silo by bucket chain conveyor. This firing workshop’s daily clinker capacity of is 3000 t. The discharging device at the silo bottom dumps the clinker into belt conveyer. The clinker is then transported to bulk loading station. Bulk clinker will be directly loaded to truck via dustless bulk spout installed at the bottom of each bin.

ENQUIRY