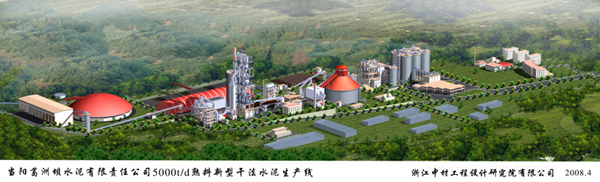

Product introduction

Pengfei EPC cement production line project includes process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and commissioning, trial operation, reaching the production standard and final delivery and other services. Mechanical equipment includes limestone crushing and conveying, clay crushing, raw coal crushing, raw coal and auxiliary raw material pre homogenization yard, raw material proportioning station, raw material grinding and waste gas treatment, raw material homogenization silo and raw material feeding into kiln, firing kiln tail, firing kiln middle and tertiary air pipe, firing kiln head, clinker conveying, clinker storage and conveying, pulverized coal preparation and metering conveying, cement proportioning station and clinker Bulk, gypsum, mixture crushing and conveying, cement grinding and conveying, cement storage and conveying, cement packaging, bagged cement loading, cement truck bulk, machine repair workshop and total material warehouse.

Process parameters

(1)Clinker output: ≥ 1500 t / d;

(2) heat consumption: ≥ 840kcal / kg clinker

(3) power consumption: ≥ 110kwh / t cement

(4) water consumption: maximum 1020m3/d

Production process

In cement production, limestone and clay are used as main raw materials, which are crushed, proportioned and milled into raw materials by ball mill, then fed into cement rotary kiln to calcine mature materials, and the clinker is added with a proper amount of gypsum, mixed with some mixed materials or additives, ground into cement by cement grinding, after that transported out of the factory by packaging machine or bulk machine. Cement production equipment usually adopts the dry cement production process. The main advantage of dry production is low heat consumption.

Main workshop, working program and main equipment

No.

|

Name of Workshop

|

Main Equipment

|

Working Programme(d/w×h/d)

|

Qty

|

1

|

Limestone

|

Single hammer crusher Feed size:≤800×800×1000mm Crushing system capacity: 350 t/h Product size: 90% ≤25mm

|

6d/w×7h/d

|

1

|

2

|

Sandstone crushing and conveying

|

High efficiency crusher Feed size:≤215 mm Crushing system capacity: 50 t/h Product size: 90% ≤20 mm

|

1d/w×7h/d

|

|

3

|

Limestone prehomogenizing and conveying

|

Stacker Capacity: 350 t/h

|

6d/w×7h/d

|

1

|

Reclaimer Capacity:150 t/h

|

7d/w×20h/d

|

1

|

4

|

Raw peat Prehomogenizing and conveying

|

Feed hopper with extractor Peat extractor: 80 t/h Peat conveying: 30 t/h

|

7d/w×4h/d

|

1

|

5

|

Raw material grinding

|

Closed circuit Ball mill Φ 4.0X9 m (precrushing /drying) Feed size: ≤25mm Product fineness: <R12% @ 80 μ Feed moisture: ≤ 8 % Product moisture: <1% Capacity: 120 t/h

|

7d/w×20h/d

|

1

|

6

|

Peat grinding

|

Closed circuit ball mill Φ 2.6x(5.25+2.25)m Feed size: ≤25mm Product fineness: <R 10% @ 80μ Feed moisture: max.12% Product moisture: <1.5% Capacity: 13-15 t/h

|

6d/w×20h/d

|

1

|

7

|

Clinker burning Temperature @ cyclones outlet ≤350±10°C

|

Five-stage cyclones, Preheater + precalciner: C1: 2- Φ 5450 mm C2: 1- Φ 5450 mm C3: 1- Φ 5450 mm C4: 1- Φ 5700 mm C5: 1- Φ 5700 mm Precalciner:1- Φ 4600 mm Temperature @ cyclones outlet ≤350±10°C Rotary kiln : Φ3.5X54m Heat consumption: ≤840kcal/kg Capacity: 1500t/d (62.5t/h) Power:220 kW , DC Fuel: Fuel oil and peat Grate cooler: mechanical drive Bed area: 39 m2 Capacity: 1500t/d

|

7d/w×24h/d

|

1

|

8

|

Cement grinding

|

Ball mill: Two closed circuit Φ3.2×13m. Product size: <R3.5% @ 80μ Capacity: 2×50 t/h PC32.5 Power: 2 × 1600 kW

|

7d/w×22h/d

|

2

|

9

|

Cement bagging

|

Two 8 spouts rotating packers Capacity: 2x100 t/h One bulky station provided.

|

6d/w×12h/d

|

2

|