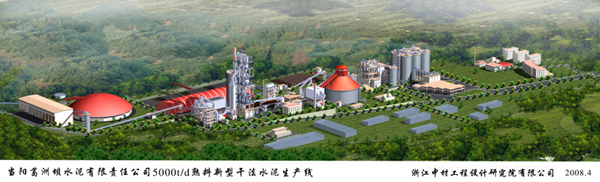

1000000 Tons / Year Slag Micro Powder Production Line

Pengfei Group provides the complete project plan of this 1000000 tons/year slag powder production line. We also manufacture process equipment of this production line. We adopt a close circuit grinding system consist of 1400×450 roller press, ф3.8×13m ball mill, and 0-SEPA3000 separator. We set sixф10×18m powder storage silos for this slag powder processing equipment. The total storage capacity is 6000 tons. We have four 220 m3/min oil-free lubricating air compressors to provide compressed air. Compressed air is dried and purified by dryer and water oil separator.

Description

Pengfei Group provides the complete project plan of this 1000000 tons/year slag powder production line. We also manufacture process equipment of this production line. We adopt a close circuit grinding system consist of 1400×450 roller press, ф3.8×13m ball mill, and 0-SEPA3000 separator. We set sixф10×18m powder storage silos for this slag powder processing equipment. The total storage capacity is 6000 tons. We have four 220 m3/min oil-free lubricating air compressors to provide compressed air. Compressed air is dried and purified by dryer and water oil separator.

Main Process Flow

This slag powder production line or slag powder processing equipment runs smoothly with high efficiency.

1. Ships transport slag into wharf. Grab bucket picks up the slag and sends it to belt conveyer. The slag is then transported to the production site.

2. Forklift conveys the slag into the dryer. Dried slag is then transported into storage silo by elevator. One storage silo has a capacity of 20000 t. Slag is discharged from the bottom of the storage silo. It is sent into mill head bin by belt conveyer and elevator.

3. Slag is grinded in the slag mill of the slag powder production line (slag powder processing equipment). Bucket feeds the grinded slag into 0-SEPA3000 separator. Dusty gas enters into coarse powder separator. Coarse powder is sent back into the mill to grind via chute. Fine slag powder is sent into two high efficient dust collectors with air flow.

4. The end product is then transported into powder storage silos by elevator. The remaining gas is then purified and exhausted into the air. Normal gas concentration is no more than 50 mg/m³.

5. Slag powder is then stored in powder storage silos of this slag powder production line or slag powder processing equipment. A bulk system installed at each silo bottom. It has a delivery capacity of 100 t/h. slag powder would be delivered in bulk.

Jiangsu Pengfei Group Co.,Ltd is a hi-tech enterprise specializing in undertaking overall contracting projects of designing, manufacturing, supplying, assembling, debugging and technical serving for industries like building materials, environmental protection, metallurgy and chemical machineries. Our products mainly consist of cement production line, rotary kiln, ball mill, raw mill, slag powder production line, cement grinding line, preheating equipment, conditioning tower, electrical control equipment, liquid ammonia tank, etc. Our slag powder manufacturing machines (slag powder processing equipment) have been well received in as many as

ENQUIRY