Description

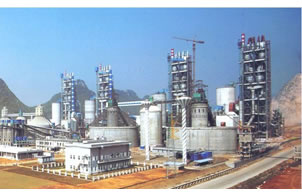

TallKee 5000t/d dry process cement production line is excellent in saving energy. It adopts various high efficient cement equipment and devices. It is designed with a smooth and tight process flow.e try to reduce production process and save transport cost. High-accuracy measuring equipment is adopted to reduce raw fuel waste and product loss. This cement production line is eco-friendly.

Methods and Techniques in Saving Energy

1. We choose energy efficient cement equipment to save electricity cost. For example, we save about 2.5 to 3 kWh/t electricity per unit by using the bucket elevator to transport raw materials.

2. A stable dust collector is installed at every source of dust in the cement production line. It not only reduces air pollution and saves production cost.

3. Raw material grinding process adopts a vertical grinding system. It could save electricity by 5 to 7 kWh/t per unit raw material compared with traditional middle-discharging system and air swept system.

4. We use circulating water to cool cement equipment. The indirect utilization rate is about 95%.

5. Our company also makes efforts to reduce heat loss from pipes and device surface. We adopt energy efficient motors and electrical fans in the cement production line.

6. TallKee adopts belt bucket elevator to feed materials into kiln tail. It reduces inlet cold air volume by 7000 m³/h compared with traditional airlift pumps. It helps increase the thermal efficiency of preheater.

7. We install VVVF electrical control devices on fans and pumps to reduce power consumption of this cement equipment. We also choose energy efficient transformers contactors and lamps.

Main Process Flow

1. Limestone Crushing and Raw Material Grinding.

In this 5000t/d dry process cement production line, Single-stage hammer crusher is used to crush limestone. It makes this process quite simple.

2. Raw Material Preheating.

The five-stage cyclone pre-heater has a low-pressure-loss technical design. It features large volute and short cylinder. Deflectors and rectifiers are also installed in this cement equipment to reduce systemic resistance. Compared with traditional preheaters, it reduces power consumption by 15-20%.

3. Burning and Clinker Cooling.

In this dry process cement production line, we use grate cooler to cool clinker. Compared with the second generation grate cooler, it reduces necessary air volume and extra waste gas volume reduced by 0.6-0.8Nm³/kg-cl. Electricity consumptions of cooling fan and waste gas exhaust fan can be therefore reduced by over 20%.

4. Coal Dust Preparation.

This cement equipment adopts vertical mill for coal dust preparation. It could save energy by about 11.0 kWh/t per unit compared with the traditional cement process low of air swept ball mill, dynamic coarse powder separator and high concentration air tank pulse bag dust collector.

Main Equipment of Cement Production Line

|

Department

|

Equipment

|

Type

|

Specification

|

|

Limestone Crushing

|

Hammer Crusher

|

TKLPC20.22A

|

Feeding Size: <1100 mm; Discharging Size: <75 mm;

Capacity: 700 t/H

|

|

Siltstone Crushing

|

Jaw Crusher

|

PE-900×1200

|

Feeding Size: <750 mm; Discharging Size: <150 mm;

Capacity: 200 t/H

|

|

Cone Crusher

|

PYS-1215

|

Feeding Size: <150 mm; Discharging Size: <30mm;

Capacity: 200 t/H

|

|

|

Limestone Prehomogenization Yard

|

Cantilever Stacker

|

|

Stack Capacity: 1400 t/H

|

|

Bridge Type Scraper Reclaimer

|

|

Reclaimering Capacity: 500 t/H

|

|

|

Siltstone Prehomogenization Yard

|

Mobile Stacker

|

|

Stack Capacity: 200 t/H

|

|

Chain Plate-Type Reclaimer

|

|

Reclaimering Capacity: 110-130 t/H

|

|

|

Raw Coal Prehomogenization Yard

|

Travelling Stacker

|

|

Stack Capacity: 200 t/H

|

|

Bridge Type Scraper Reclaimer

|

|

Reclaimering Capacity:100 t/H

|

|

|

Raw Meal Grinding And Waste Gas Treatment

|

Vertical Mill

|

MLS453

|

Capacity: 360-400 t/H; Feeding Moisture: <6%; Output Moisture: <0.5%; Feeding Size: <100 mm;

Output Size: R80ΜM <12%

|

|

Raw Meal Mill Fan

|

|

Air Volume: 860000 m³/H;

Full Pressure: 9500 Pa

|

|

|

Kiln Inlet High Temperature Fan

|

|

Air Volume: 860000 m³/H;

Full Pressure: 7500 Pa

|

|

|

High Concentration Electrostatic Precipitator

|

BS930

|

Electric Field Sectional Area: 310m2;

Air Volume: 820000 m³/H;

Outlet Dust Content (Standard): ≤50mg/m3

|

|

|

Coal Powder Preparation

|

Vertical Mill

|

MPF2116

|

Capacity: 38-45 t/H; Feeding Moisture: <12%; Output Moisture: <1%; Feeding Size: <25 mm; Output Size: R80ΜM<12%

|

|

Firing System

|

Rotary Kiln

|

Φ4.8×74 m

|

Inclination: 4%; Support No.: 3; Speed: 0.6-4.0 r/Min;

Installed Power: 630kw; Capacity: 5000 t/D

|

|

Preheater And Calciner

|

Five Stage Double Series

|

C1:4—Φ5.0m; C2:2—Φ6.9m; C3:2—Φ6.9m; C4:2—Φ7.2m; C5:2—Φ7.2m; Calciner: Φ7.2×30.0 m; Capacity: 5000 t/D

|

|

|

Control Flow Grate Cooler

|

LBT36352

|

Grate Bed Area: 119.6 M²; Feeding Temperature: 1400℃;

Discharging Temperature: 65℃+ Ambient Temperature

|

|

|

Kiln Outlet Electrostatic Precipitator

|

|

Air Flow: 550000 m³/H; Electric Field Sectional Area: 196 m²;

Inlet Dust Content: ≤30 G/M³; Outlet Dust Content:≤50mg/Nm³

|