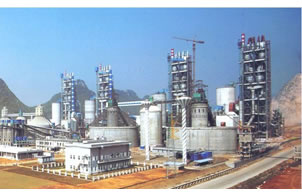

Description of 100,000 Tons/Year Small Cement Production Equipment:

This 100,000 tons/year small concrete processing plant is a kind of small and medium size calcining machine of cement clinker, and it is designed with deflected fire control system. In general, it has the advantages of strong ventilation capacity and quick calcining and cooling down. And technical services are also available.

Parameters of 100,000 Tons/Year Small Concrete Processing Plant:

| No. | Name and specification | Technical parameters | Amount | Remarks |

| 1 | Apron feeder B1000×12.1m |

Q: 18-110T/h N:15kW | 1 | TallKee |

| 2 | PE600×900 crusher | Q: 56T/h N: 55KW | 1 | |

| 3 | HD8964L-A bag filter | Q: 4200-5200m3/h N: 7.5KW+0.37KW |

1 | TallKee |

| 4 | FF300S flap valve | Q: 6-12T/h | 1 | |

| 5 | TD75 rubber belt conveyor | B650×23.022m Q: 140T/h N:5.5kW | 1 | |

| 6 | PC1010 hammer crusher | Q: 60-80T/h N=132kW | 1 | |

| 7 | MW-66-12B sleeve environmental protection equipment | Q: 10800-14400m3/h | 1 | |

| 8 | Fan | C4-73-11-No5.5C Q=14700m3/h , N=22kW | 1 | |

| 9 | TH400 bucket elevator | Q: 58 m3/h N:15kW | 1 | |

| 10 | BZ-1 bar valve | 600×600 | 2 | |

| 11 | TDG65 speed regulation scales | Q: 24T/h | 2 | |

| 12 | Gate | 400×400 | 4 | |

| 13 | TDG50 speed regulation scales | Q: 6.5T/h | 2 | |

| 14 | TDG50 speed regulation scales | Q: 1.5T/h | 2 | |

| 15 | HD8948C bag filter | Q: 2000-3000m3/h N: (5.5+0.25)KW |

3 | |

| 16 | TD75 rubber belt conveyor | B500; L: 38.85m N:80T/h; N:5.5kW |

1 | |

| 17 | TD75ruber belt conveyor | B500×17.1m; α:17°; Q:15T/h; N:3KW |

1 | |

| 18 | 400×600 clay crusher | Q=10-15T/h; N:15kW; dv≤400mm; dr≤25mm |

1 | |

| 19 | TD75 rubber belt conveyor | B500×30.5m; Q:80T/h α:15°42'; N:5.5kW |

1 | |

| 20 | TD75 rubber belt conveyor | B500×6.1m;Q:15-20T/h α:10°23' |

1 | |

| 21 | TH315 bucket elevator | C=9.763 Q:35m3/h; N:7.5kW | 1 | TallKee |

| 22 | SM500 coal crusher | Q: 5-8T/h; N:7.5kW | 1 | |

| 23 | TH315 bucket elevator | C=13.347m Q:35m3/h; N:7.5kW | 1 | |

| 24 | Gate | 200×200 | 1 | |

| 25 | GZIF electrical vibration machine | N: 60W | 1 | |

| 26 | 9-19No6.3A fan | Q:3972m3/h; P:9650Pa; N:18.5kW | 1 | |

| 27 | butterfly valve | 1 | ||

| 28 | GJH2212 dryer | φ2.2×12m; Q:10-60T/h; N:22kW | 1 | |

| 29 | DFF300S electric valve | Q:6-12T/h; N:0.55kW | 1 | |

| 30 | TH315 bucket elevator | C:26.659; Q:35m3/h; N:11kW | 1 | |

| 31 | CLK4×60 diffusion environmental protection equipment | Q=27000m3/h | 1 | |

| 32 | DFF220 electric flap valve | N:0.37kW | 1 | |

| 33 | CWB-15 horizontal electric environmental protection equipment | Q=30000-37400m3/h; loc>99.5% | 1 | |

| 34 | G4-73-11No.9D fan | Q=24000m3/h; P: 2670Pa; N:30kW | 1 | |

| 35 | LS200 screw conveyor | L: 11m; N:2.2kW | 1 | TallKee |

| 36 | MB2270 ball mill | φ2.2×7m; Q:20-25T/h; N:380KW | 1 | |

| 37 | DFF400S electric flap valve | Q:20-60T/h; N:0.75kW | 1 | |

| 38 | TH400 bucket elevator | C=21.152; Q:58 m3/h; N:15kW | 1 | |

| 39 | QLL4.0m powder separator | N:45kW; φ4m | 1 | TallKee |

| 40 | DFF400S electric flap valve | 2 | ||

| 41 | LS400 | L=15.500m; Q:36.2m3/h; N:11kW | 1 | |

| 42 | TH315 bucket elevator | C=15.395; Q= 35m3/h; N:11kW | 1 | |

| 43 | WL300 single-pipe machine | φ300×1460m; Q:35T/h; N:3kW | 1 | |

| 44 | LS400 screw conveyor | L=13.500m; Q:45m3/h; N:7.5kW | 1 | |

| 45 | TH315 bucket elevator | C=21.539; Q= 35m3/h; N:11kW | 1 | |

| 46 | CLK2×7diffusion cyclone environmental protection equipment | Q:12900-18400m3/h | 1 | |

| 47 | CWB.7 horizontal electric environmental protection equipment | Q:15000-18700m3/h | 1 | |

| 48 | DFF150 electric flap valve | 0.37-0.55Kw | 1 | |

| 49 | 4-72-11No.6C fan | Q:15800m3/h; P:2480Pa; N:18.5kW | 1 | |

| 50 | LS400 screw conveyor | L=23.500m; Q:36.2m3/h; N:11kW | 1 | |

| 51 | LS400 screw conveyor | L=24.500m; Q:36.2m3/h; N:11kW | 1 | |

| 52 | LS400 screw conveyor | L=24.500m; Q:36.2m3/h; N:11kW | 1 | |

| 53 | LS40 screw conveyor | L=22.500m; Q:36.2m3/h; N:11kW | 1 | |

| 54 | HD8948C bag filter | Q:2000-3000m3/h; N:5.5kW+0.75kW | 2 | TallKee |

| 55 | TH315 bucket elevator | C=23.587m; Q:35m3/h; 11KW | 1 | |

| 56 | Gate | 300×300 | 1 | |

| 57 | LS400 screw conveyor | L=8.500m; Q:36.2m3/h; N:5.5kW | 1 | |

| 58 | rigid impeller machine | 300×300; 1.5kW | 1 | |

| 59 | TH315 bucket elevator | C=15.395m; Q:35m3/h; 11KW | 1 | |

| 60 | TH315 bucket elevator | C=22.051; Q:35m3/h; 11KW | 1 | |

| 61 | SWL250×2000 double-pipe machine | Q:11-34m3/h; N:7.5kW | 1 | |

| 62 | LXC-H spiral electronic scales | 1 | ||

| 63 | 2J5.5×3000 double-shaft machine | Q:25T/h; N:15kW | 1 | |

| 64 | QPY36 granulator | φ3.6m; Q:18-22T/h; N:18.5KW | 1 | TallKee |

| 65 | TD75 belt conveyor | B500×6.5m; Q:120T/h; N:5.5kW | 1 | |

| 66 | CD0.5-6A electric hoist | 1 | ||

| 67 | φ3×11m mechanical shaft kiln | Q:11-13T/h | 1 | |

| 68 | L94WD fan | Q:359m3/h; P:294KPa; N:245kW | 1 | |

| 69 | ZLX-9 sound eliminator | 1 | ||

| 70 | LS200 screw conveyor | L=4m; 2.2kW | 1 | |

| 71 | LS200 screw conveyor | L=8m; 2.2kW | 1 | |

| 72 | LS200 screw conveyor | L=11m; 2.2kW | 1 | |

| 73 | PEX150×750 crusher | Q:8.35T/h; N:15kW | 1 | |

| 74 | B360 horizontal sealer | L=5.5m; Q:21T/h; N:5.5kW | 1 | |

| 75 | TH315 bucket elevator | C:22.563m; 11kW | 1 | |

| 76 | HD8948C bag filter | Q: 2000-3000m3/h; 5.5kW-2P | 1 | |

| 77 | CWB-3 horizontal electric environmental protection equipment | Q:4500-7200m3/h | 1 | TallKee |

| 78 | DFF150 electric flap valve | 0.37-0.55kW | 1 | |

| 79 | C648No.5C fan | Q:7200m3/h; P:1850Pa; N:7.5kW | 1 | |

| 80 | LS200 screw conveyor | L=6.5m | 1 | |

| 81 | Gate | 400×400 | 4 | |

| 82 | GZ-3 electric vibrating machine | Q:25T/h | 4 | |

| 83 | TD-75 rubber belt conveyor | B500×30m; 11kW | 1 | |

| 84 | PE250×400 crusher | 250×400; Q:4-14m3/h; N:15kW | 1 | TallKee |

| 85 | TH315 bucket elevator | C:19.491m;Q:35m3/h; 11kW | 1 | |

| 86 | TH315 bucket elevator | C:17.433m;Q:35m3/h; 11kW | 1 | |

| 87 | Gate | 300×300 | 3 | |

| 88 | Belt scales TDG650 | Q:24T/h | 1 | |

| 89 | Belt scales TDG500 | Q:6.5T/h | 1 | |

| 90 | Belt scales TDG500 | Q:1.5T/h | 1 | |

| 91 | MB2275 grinder | φ2.2×7.5m; Q=16T/h; | 1 | |

| 92 | DEF400S electric flap valve | Q:20-60T/h; N:0.75kW | 1 | |

| 93 | CLK2×6 diffusion cyclone environmental protection equipment | Q:12120-13500m3/h | 1 | TallKee |

| 94 | DFF150 electric flap valve | 1 | ||

| 95 | CWB6 horizontal electric environmental protection equipment | Q:14200-17000 m3/h; loc>99.5% | 1 | |

| 96 | LS400 screw conveyor | L:13.500m; Q:36.2 m3/h; N:5.5kW | 1 | |

| 97 | Y5-48-No.6.3C fan | Q:12030 m3/h; P:2592Pa; N:15kw | 1 | |

| 98 | TH315 bucket elevator | C:21.027m; 11kW | 1 | |

| 99 | QLL4.0 powder separator | N:30kW; 3.5m | 1 | |

| 100 | DFF400S electric flap valve | 0.75kW | 1 | |

| 101 | LS400 screw conveyor | L:13.500m; Q:36.2m3/h N:5.5kW | 1 | |

| 102 | TH315 bucket elevator | C:15.395m; Q:35 m3/h; 11kW | 1 | |

| 103 | TH315 bucket elevator | C:21.539m; Q:35 m3/h; 11kW | 1 | |

| 104 | LS400 screw conveyor | L:23.000m; Q:36.2m3/h N:11kW | 1 | |

| 105 | LS400 screw conveyor | L:25.000m; Q:36.2m3/h N:11kW | 1 | |

| 106 | LS400 screw conveyor | L:24.000m; Q:36.2m3/h N:11kW | 1 | |

| 107 | HD8948C bag filter | Q:2000-3000m3/h; N:5.5kW+0.75kW | 1 | |

| 108 | Gate | 300×300 | 6 | |

| 109 | Rigid impeller feeder | 300×300 | 6 | |

| 110 | LS400 screw conveyor | L:21.500m; Q:36.2m3/h N:11kW | 1 | |

| 111 | TH315 bucket elevator | C:14.371m; N= 11kW | 1 | |

| 112 | D870 rotary screen | N:2.2kW; Q:30T/h | 1 | |

| 113 | G4201 packaging machine | Q:30T/h; N:11kW | 1 | |

| 114 | MW-N-140-SP bag filter | Q:8400-16800; N:3kW+2.2kW+1.5kW | 1 | TallKee |

| 115 | butterfly valve | φ200 | 3 | |

| 116 | 4-72-11No.5A fan | Q:11830m3/h; P:2844Pa; N:15kW | 1 | |

| 117 | LS-200screw conveyor | L=5m; N:2.2kW | 2 | |

| 118 | LS400screw conveyor | L=4.5m; Q:36.2 m3/h; N:5.5kW | 1 | |

| 119 | rubber belt conveyor | B800×4000; N:3kW | 1 | |

| Total number | ||||

| Laboratory | ||||

| Physical examination part | ||||

| 1 | Press machine | 30 type | 1 | TallKee |

| 2 | Anti-fracture machine | 50 type | 1 | |

| 3 | cement mortar mixer | 411A | 1 | |

| 4 | Cement mortar vibration platform | 85 type | 1 | |

| 5 | Electric jump table | 1 | ||

| 6 | Cement paste blender | 1 | ||

| 7 | Boiling tank | 1 | ||

| 8 | Consistency meter | 2 | ||

| 9 | Blain specific surface meter | 1 | ||

| 10 | Psychrometer | 2 | ||

| 11 | Temperature controller | 1 | ||

| 12 | Geotherm wire | 1 | ||

| 13 | Anti-pressure fixture | 1 | ||

| 14 | Anti-bending fixture | 1 | ||

| 15 | Cement paste pot | 1 | ||

| 16 | Test needle | 2 | ||

| 17 | Paste cup | 1 | ||

| 18 | Feeding hopper | 2 | ||

| 19 | Nickel crucible holder | 1 | ||

| 20 | Spray head(aluminum alloy) | 2 | ||

| 21 | Disc grinder | φ175 | 1 | |

| 22 | standard sand | 1 | ||

| 23 | K-Bcmp | |||

| Chemical analysis part | ||||

| 24 | Chamber type electric resistance furnace | 8X-4-10 | 1 | |

| 25 | Constant temperature oven | 101-2 | 1 | |

| 26 | Electro-optic analytical balance | TG328A | 2 | |

| 27 | Electro-optic analytical balance | TG328B | 1 | |

| 28 | Water distiller | 10t/h | 2 | |

| 29 | Magnetic force heating mixer | 90-2 | 2 | |

| 30 | Platinum crucible | 30ml | 2 | |

| 31 | Oxygen recorder | 1 | ||

| 32 | Infrared ray dryer | 40×45 | 2 | |

| 33 | Roberval's balance | 200g | 2 | |

| 34 | Burdening computer | PL-1 | 1 | |

| 35 | Porcelain crucible | φ15 φ20 φ25 | 60 | |

| 36 | Ark | 28×50 | 30 | |

| 37 | Volatilization crucible | 30ml | 20 | |

| 38 | Burette stand | Marble | 10 | |

| 39 | Thermometer | ≤100℃ | 10 | |

| 40 | Watch glass | φ100 | 10 | |

| 41 | φ60 | 10 | ||

| 42 | Dryer | φ240 | 5 | |

| 43 | φ200 | 5 | ||

| 44 | Electric furnace | 800W | 3 | |

| 45 | Plastic wares | |||

| 46 | Bi-join ball | 1 | ||

| 47 | Ion exchange column | φ50×600 | 4 | |

| 48 | Water feeder(cement paste) | 100-170ml | 4 | |

| 49 | Water feeder(mortar) | 238ml | 2 | |

| 50 | Ox horn scoop | 10 | ||

| 51 | Plastic scoop | 5 | ||

| 52 | Porcelain plates | 12×16″ | 4 | |

| 53 | crucible tong | Stainless steel 20″ | 2 | |

| 54 | Latex tubing | 5×7 | 20 | |

| 55 | Scale bulb | 6.3W | 50 | |

| 56 | Stainless steel tweezers | 16cm | 10 | |

| 57 | Water bath | Two holes | 1 | |

| 58 | Water sieve | φ125 0.08 | 10 | |

| 59 | Water pressure gauge | 0.16MPa | 2 | |

| 60 | Tee joint | 4 | ||

| 61 | Dry screen | φ300 0.9 | 2 |

Established in 1994, TallKee is a professional manufacturer of 100,000 tons/year small concrete processing plant in China. Besides 100,000 tons/year small concrete processing plant, we also provide customers worldwide with cement rotary kiln, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, cooling equipment, drying equipment, compound fertilizer equipment, packing machine, chemical equipment and electrical control system. With the certification of ISO9000 and CE, our products have been well received by customers from as many as .